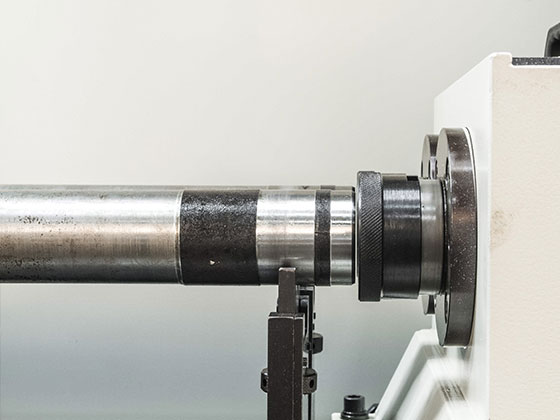

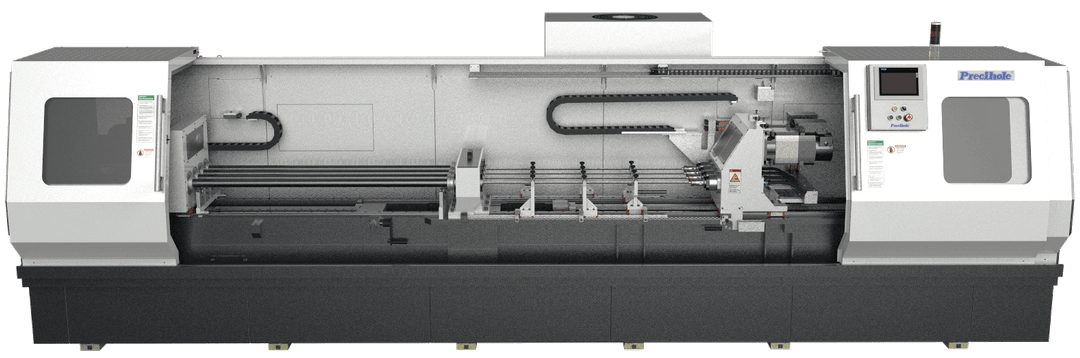

These machines are built to manufacture high precision parts and can be customized to suite high volume requirements. These machines provide excellent straightness, surface finish and bore tolerance. Length to diameter ratios of up to 125 is possible.

Machine Features

| Description | GVN08 | GVN12 | GVN25 | GVN40 |

|---|---|---|---|---|

| Drilling Diameter Range (mm) | Ø2 – Ø8 | Ø3 – Ø12 | Ø5 – Ø25 | Ø8 – Ø40 |

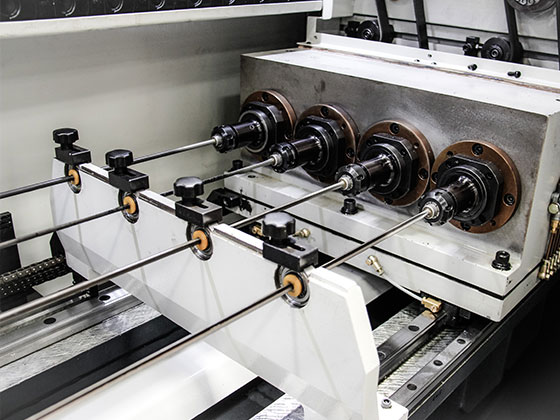

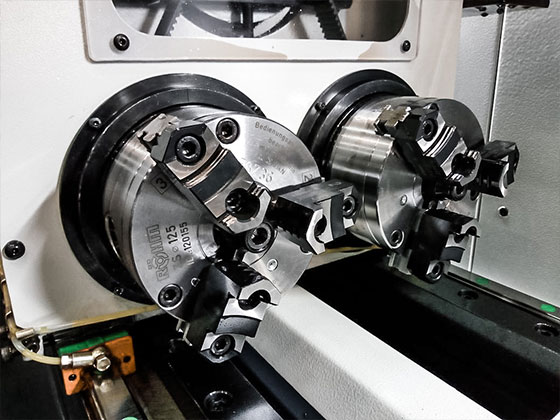

| Spindles (Nos.) | 1/2/4 | 1/2 | 1/2 | |

| Max. Drilling Depth (mm) | 400 / 600 / 1000 / 1200 | |||

| Part OD Range (mm) | 10 – 50 | 15 – 75 | 15 – 100 | |

| Part Clamping System | Hydraulic Cone Clamping / Chuck Clamping | |||

| Max. Component Weight (kg) | 30 | 50 | 70 | |

| Counter Rotation Speed (rpm) | 250 | 250 | 200 | 150 |

| Drill Feed Range (mm/min) | 0 – 1000 | |||

| Rapid Traverse (mm/min) | 4000 | |||

| Power per Spindle (kW) | 1.5 | 2.2 | 7.5 | 15 |

| Spindle Speed (rpm) | 2000 – 12000 | 1200 – 10000 | 500 – 7500 | 300 – 3200 |

| Coolant Tank Capacity (liters) | 800 | 1200 | 2000 | 3000 |

| Max. Coolant Pressure (bar) | 100 | 90 | 80 | 70 |

| Description | GVN08 | GVN12 | GVN25 | GVN40 |

|---|---|---|---|---|

| Drilling Diameter Range (in) | Ø0.08 – Ø0.3 | Ø0.12 – Ø0.47 | Ø0.19 – Ø1 | Ø0.31 – Ø1.57 |

| Spindles (Nos.) | 1/2/4 | 1/2 | 1/2 | |

| Max. Drilling Depth (in) | 16 / 24 / 40 / 48 | |||

| Part OD Range (in) | 0.4 – 2 | 0.6 -3 | 0.6 – 4 | |

| Part Clamping System | Hydraulic Cone Clamping / Chuck Clamping | |||

| Max. Component Weight (lbs) | 109 | 111 | 155 | |

| Counter Rotation Speed (rpm) | 250 | 250 | 200 | 150 |

| Drill Feed Range (in/min) | 0 – 40 | |||

| Rapid Traverse (in/min) | 150 | |||

| Power per Spindle (hp) | 2 | 3 | 10 | 20 |

| Spindle Speed (rpm) | 2000 – 12000 | 1200 – 10000 | 500 – 7500 | 300 – 3200 |

| Coolant Tank Capacity (gal) | 211 | 320 | 530 | 800 |

| Max. Coolant Pressure (psi) | 1500 | 1350 | 1200 | 1000 |