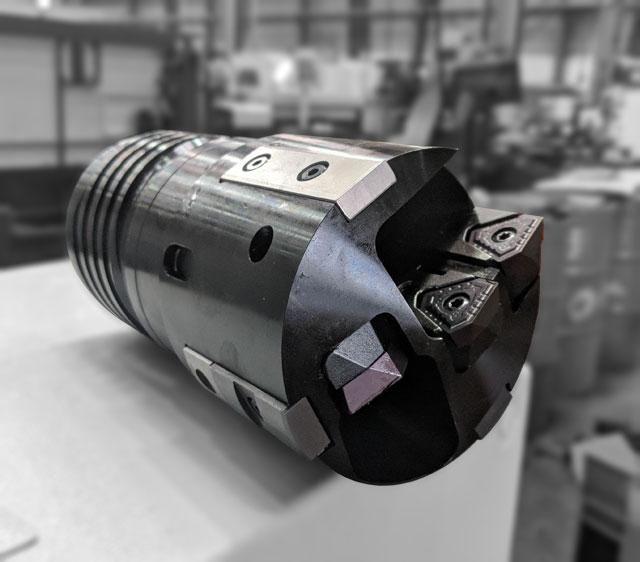

Ejector Drilling is similar to BTA Drilling operation with the difference that it has Twin tubes instead of a single tube.The high pressure Coolant is pumped to the cutting face through the annular area between the outer tube and the inner tube. There is a special connector for holding both the tubes and also to feed the high pressure coolant.The pressure head with rear coolant sealing that is required in BTA drilling is eliminated here and only a guide bush is needed.The Chips generated are evacuated through the inner tube where ejection effect is generated at the rear end to help in chip evacuation.The area for chip discharge is comparatively less than BTA and hence the evacuation is not as efficient particularly in smaller sizes.Since the tube diameter is larger than BTA Drilling the torsional strength also goes up. This can be an advantage to go for higher feeds. This is usually used to retrofit conventional machines for deep hole drilling.