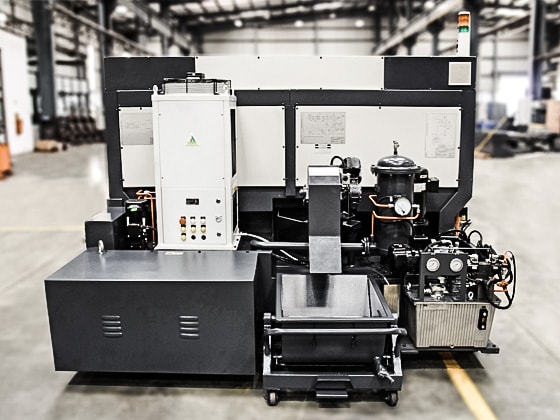

These machines are designed for small hole diameter drilling usually required in medical implants. They also find application in aerospace and automotive industries. Precihole’s own component manufacturing experience over 30 years helps ensure that all the necessary complexities in small hole drilling of such applications are incorporated in the design of key features on this machine. Machine can be customized to accommodate production volume requirements and provide excellent straightness, surface finish and bore tolerance.

Machine Features

| Description | GDN06C |

|---|---|

| Drilling Diameter Range (mm) | Ø1 – Ø6 |

| Spindles (Nos.) | 1/2 |

| Max. Drilling Depth (mm) | 300 |

| Part OD Range (mm) | 40 |

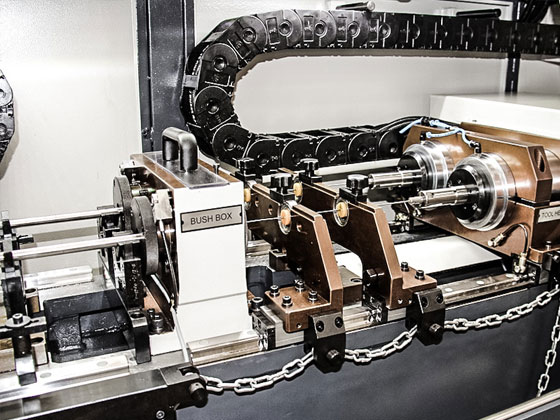

| Part Clamping System | Hydraulic Cone Clamping / Chuck Clamping |

| Max. Component Weight (kg) | 10 |

| Counter Rotation Speed (rpm) | 500 – 1000 |

| Drill Feed Range (mm/min) | 0 – 1000 |

| Rapid Traverse (mm/min) | 4000 |

| Power per Spindle (kW) | 1.5 |

| Spindle Speed (rpm) | 1000 – 24000 |

| Coolant Tank Capacity (liters) | 380 |

| Max. Coolant Pressure (bar) | 200 |

| Description | GDM06C |

|---|---|

| Drilling Diameter Range (in) | Ø0.04 – Ø0.25 |

| Spindles (Nos.) | 1/2 |

| Max. Drilling Depth (in) | 12 |

| Part OD Range (in) | 1.5 |

| Part Clamping System | Hydraulic Cone Clamping / Chuck Clamping |

| Max. Component Weight (lbs) | 22 |

| Counter Rotation Speed (rpm) | 500 – 1000 |

| Drill Feed Range (in/min) | 0 – 40 |

| Rapid Traverse (in/min) | 150 |

| Power per Spindle (hp) | 2 |

| Spindle Speed (rpm) | 1000 – 24000 |

| Coolant Tank Capacity (gal) | 100 |

| Max. Coolant Pressure (psi) | 3000 |