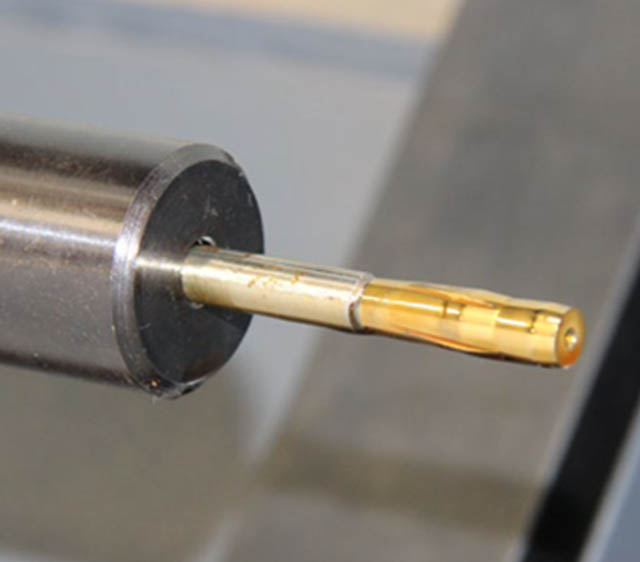

Rifling process is used to produce rifle grooves into barrels. This process is very specialized and one of the most critical process for producing a rifled barrel. We provide thre different processes; Button Rifling Machines, Broach Rifling Machines and Cut Rifling Machines by Precihole. Button Rifling Machines incorporates the latest features to form precision grooves in small caliber weapon systems. Broach rifling for large caliber weapon systems, creates spiral grooves in the barrel by removing steel using a hook cutter. Cut Rifling Machines (also known as Single Point Cut Rifling) cut spiral grooves in the barrel by machining steel using a hook cutter.