Machines

Deep Hole Drilling & Hole Finishing Machines

Our complete line of deep hole drilling solutions by Precihole Machine Tools are designed to meet the needs of the modern machine shop now and for many years to come. These machines offer a wide range of features and capabilities making them versatile to suit a myriad of applications in various industries. The multi-axis and multi-spindle versions boost productivity many folds without compromising on accuracy and rigidity.

Explore Machines by Series

With 3 decades of combines experience,we have produced solutions to various industry segments. If your industry requires an application in deep hole drilling, we have a solution. Standard as well as Custom build solutions for specific industry applications that ensure the required hole specifications are met. Our solutions can be found in each and every Industry worldwide.

Single Axis Gun Drilling

This series is our most popular series and has 100s of applications in dozens of industries. This series covers drilling range from Ø2mm to Ø40 mm and lengths of parts up to 1500 mm. Machines are designed for 3 shift production mode and provide all the features for excellent output parameters like straightness, bore tolerance and surface finish.

Pull Reaming

Precihole’s pull reaming machine series combines high speed sizing of holes. Surface finish as well as consistency of holes across the length of the part is vastly improved after pull reaming.Primary application of this series is in firearm manufacturing for all small caliber weapon systems.

Vertical Honing

Precihole’s Vertical Honing Series is versatile and incorporates all the necessary features to produce excellent sizing and surface finish in a variety of parts in various industries. Precihole also provides all the fixturing and tooling needed for sizes ranging from Ø5 mm to Ø40 mm in this series.

Single Axis Rifling Machine

Button Rifling Machines incorporate the latest features to form precision grooves in small caliber weapon systems. The rifling button is pulled and rotated precisely through the barrel. Precision in rifling is critical. The machine uses anti backlash helical guides and rotary encoder to interpolate linear and rotary motion. This produces rifling twists exactly as needed by the rifling tool. Machine features include load monitoring that graphs the rifling pull load on the HMI. Operator can monitor the rifling operation on screen, output to printer or flash disk if required.

Facing & Centering

Facing, Chamfering and centering machines are specifically designed to accommodate high volume needs to face, center and chamfer cylindrical shafts at both ends in one setup. The tool plunges into the work piece ends and does all 3 operations in one shot. Cycle times are typically less than 30s. This machine is ideally suited for use in firearm and automotive industries.

Broach Rifling Machine

We are proud to be in a very small elite group of machine suppliers capable to provide a Precihole broach rifling machine for large caliber weapon systems. Broach rifling creates spiral grooves in the barrel by removing steel using a hook cutter.

Cut Rifling

Precihole is one of the few machine manufacturers in the world that can supply a cut rifling machine for cutting grooves on small bore caliber weapon systems. Cut Rifling Machines (also known as Single Point Cut Rifling) cut spiral grooves in the barrel by machining steel using a hook cutter.

BTA Drilling

Precihole’s BVN series BTA deep hole drilling machines are well designed and robust to take heavy loads while drilling large holes. This series covers hole drilling from Ø20 mm to Ø250 mm solid and counter boring to Ø400 mm. Work piece lengths of 500mm to 10m can be accomodated on these machines. These machines are configurable with features depending on accuracy requirements and type of parts to be drilled.

Skiving and Roller Burnishing

Precihole’s Skiving and Roller burnishing machine combines state-of-the-art features to offer a high speed high volume production of hydraulic cylinders. This technology is about 40 times faster than honing and results in excellent output parameters needed on hydraulic cylinder tubes.

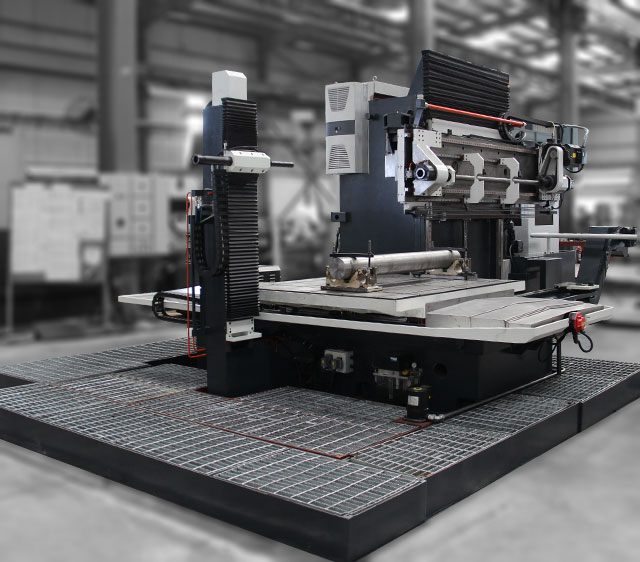

Three Axis Gun Drilling

These machines are designed for prismatic parts that need multiple holes on the face. The use of CNC controls to interpolate X, Y and Z axes movements gives precise location and repeatability for holes. Applications include cooling holes in mold plates, glass molds as well as long plates needing through holes in them.

Column Type Drilling

This series is specifically designed for large mold bases and tube sheets. Machines can be configured for gun drilling mode or BTA mode as per requirements. This series can incorporate 3 to 7 axes of CNC depending on features selected.

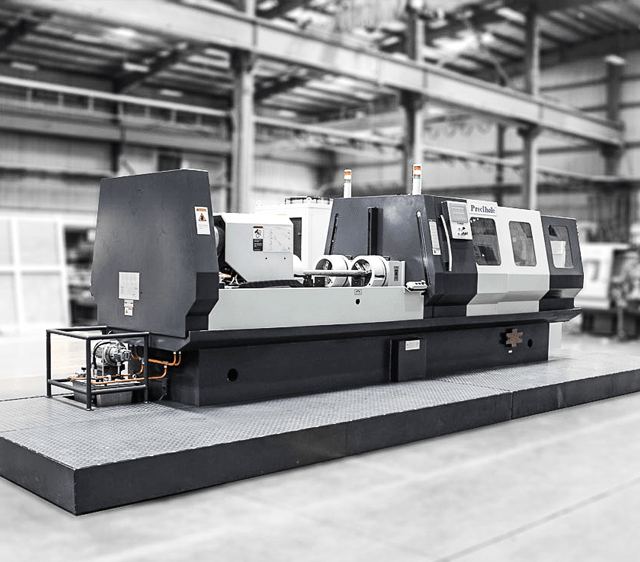

Horizontal Honing

Precihole’s horizontal honing machine series is designed to provide all the features necessary to hone IDs in cylindrical shafts. Applications range from Oil & Gas industry, Energy and Military. These machines can be configured to hone parts from Ø30 mm to Ø400 mm up to 10m in length.

Micro Gun Drilling

This series is specially designed to meet all the requirements of very small hole drilling from Ø1 mm to Ø6 mm. Motorized spindles, high pressure coolant pumps as well as tool breakage monitoring systems are standard on this series. Many work holding options are also offered on these machines depending on application requirements.

Multi Spindle Multi Axis

Precihole specializes in custom manufacturing deep hole drilling and hole finishes machines that are not covered in our standard series. With over 30 years of special machine design and development experience under its belt and a team of highly experienced concept and design engineers, Precihole prides itself to be one of the best SPM manufacturers in the industry.

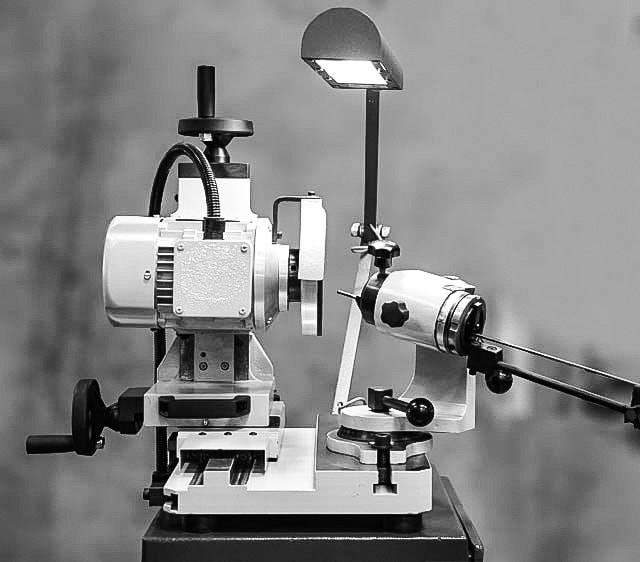

Gun Drill Regrinding

Precihole’s Gun drill regrinding machine provides users with a quick and accurate way to regrind their gun drills for multiple uses. The machine does not require skilled labor to operate and regrinds drills from Ø2 mm to Ø30 mm in one setting.

Barrel Straightening Press

Precihole manufactures a compact and precise straightening press for gun barrels. Barrel blank straightness is a very important factor that determines the accuracy of the weapon system. Barrel is a long slender shaft that is likely to bend during many stages of heat treatment and machining as it goes through all the way from bar stock to a gun ready profiled and chambered barrel. It isverysimple to use and does not require any special operator skills.