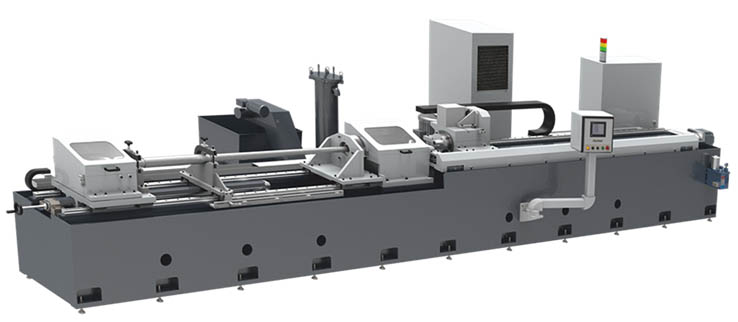

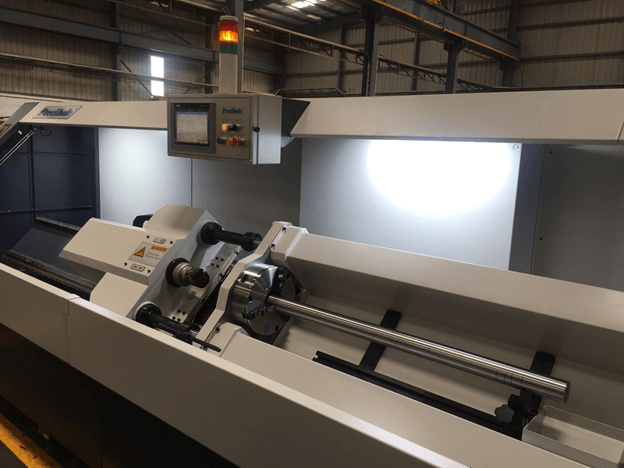

We are proud to be in a very small elite group of machine suppliers capable to provide a Precihole broach rifling machine for large caliber weapon systems. Broach rifling creates spiral grooves in the barrel by removing steel using a hook cutter. The linear and rotary motion of the hook cutter are precision controlled for accuracy using a servo drive and ball screw or rack and pinion mechanism. The broach cutters are progressive in size and each cutter cuts a size slightly bigger than the previous one. The fine filtration system on the machine ensures that the system gets coolant at requires rates and the swarf is evacuated properly from the barrel.

Salient Features

| Description | BRM40 | BRM200 |

|---|---|---|

| Rifling Size Range | 20-40 mm | 40-205 mm |

| Spindles | 1 | 1 |

| Max. Rifling Depth | 1000/2500 mm | 2000/10000 mm |

| Barrel OD Range | 50-100 mm | 100-400 mm |

| Barrel Clamping System | 3 Jaw Self Centering Chuck | 3 Jaw Self Centering Chuck |

| Max. Component Weight | 100 kgs | 10000 kgs |

| Rifling Feeding Range | 0-7 m/min | 0-7 m/min |

| Rifling Pull Force | 10 tons | 30 tons |

| Twist Rate | Left Hand / Right Hand | Left Hand / Right Hand |

| Pregressive Twist | Programmable | Programmable |

| Description | BRM40 | BRM200 |

|---|---|---|

| Rifling Size Range | 0.78-1.57 in | 1.5-8.00 in |

| Spindles | 1 | 1 |

| Max. Rifling Depth | 40-100 in | 80-400 in |

| Barrel OD Range | 2-4 in | 4-16 in |

| Barrel Clamping System | 3 Jaw Self Centering Chuck | 3 Jaw Self Centering Chuck |

| Max. Component Weight | 220 lbs. | 22000 lbs. |

| Rifling Feeding Range | 0-275 in/min | 0-275 in/min |

| Rifling Pull Force | 10 tons | 30 tons |

| Twist Rate | Left Hand / Right Hand | Left Hand / Right Hand |

| Pregressive Twist | Programmable | Programmable |